Enter your ZIP code for pricing and local availability.

Making Redbreast

Redbreast is produced from grain to glass at one distillery – Midleton Co. Cork. Single Pot Still Whiskey is regarded as the quintessential style of Irish whiskey, safeguarded and nurtured under the watchful eye of the Midleton Distillery for almost two hundred years.

Considered the definitive expression of the Single Pot Still art, Redbreast is made using a unique combination of malted and unmalted barley. It is then triple distilled in traditional copper pot stills and matured in ex-bourbon and ex-sherry casks. This process gives Redbreast the significant complex silky mouth feel and sherry notes that Redbreast is renowned for.

Irish Barley

Irish barley, plump from the fields at harvest time, is the key raw ingredient at Midleton Distillery. This barley is purchased from local farmers, many of whom have been supplying Midleton Distillery for generations. Their dedication to quality, and their awareness that only the best barley will be acceptable, ensures that only the very finest grains pass through the gates at Midleton.

This brings us to the first main difference between pot still whiskey and other whiskey styles - the use of malted and unmalted barley in the 'mashbill'.

Unmalted Barley

This is simply barley which has been harvested, dried and delivered to the distillery. If this barley was placed between your teeth, it would feel firm and difficult to bite through.

Malted Barley

The process of malting barley begins by soaking barley in tanks of water for a number of hours before laying it out on the large floors of the malt house. The temperature in the malthouse is kept above 18oC, and thus the grains of barley, thinking they have been planted in the ground, begin to sprout. This causes the grain to call on its starch reserves, stored within its cells, to be used as a fuel for growth in providing the grain with both a root and a stem. As soon as this change commences, the maltster applies heat to the barley, in closed smokeless kilns, and this heat ceases any further growth. This barley is now malted barley and the malting process has taken about 4 days. Visually, it is almost identical to unmalted barley but when placed between your teeth, it is crunchy and sweet to taste. The primary reason for malting barley is to make the starch accessible to the yeast during the fermentation stage.

-

Milling

This is the stage at which the second major difference between Redbreast Single Pot Still Irish Whiskey and other whiskey styles comes to the fore. Depending on the particular distillate which the distiller requires, different proportions of unmalted and malted barley are assembled and milled into coarse flour called 'grist', which contains all the parts of the grain including the flour and the husk. The grist or ‘mashbill’ is then sent forward for mashing. The milling process at Midleton Distillery is a complex and impressive process due to the fact the mill must accommodate both malted and unmalted barley. Both grains need to be treated or ‘conditioned’ separately before being fed into the mill and the mill also needs settings to accommodate the soft malt and the firm barley grains. Traditionally, barley malting was performed at the Distillery but nowadays malt is supplied by Maltsters who can create a malted barley which is exactly to the Midleton distillers specifications.

-

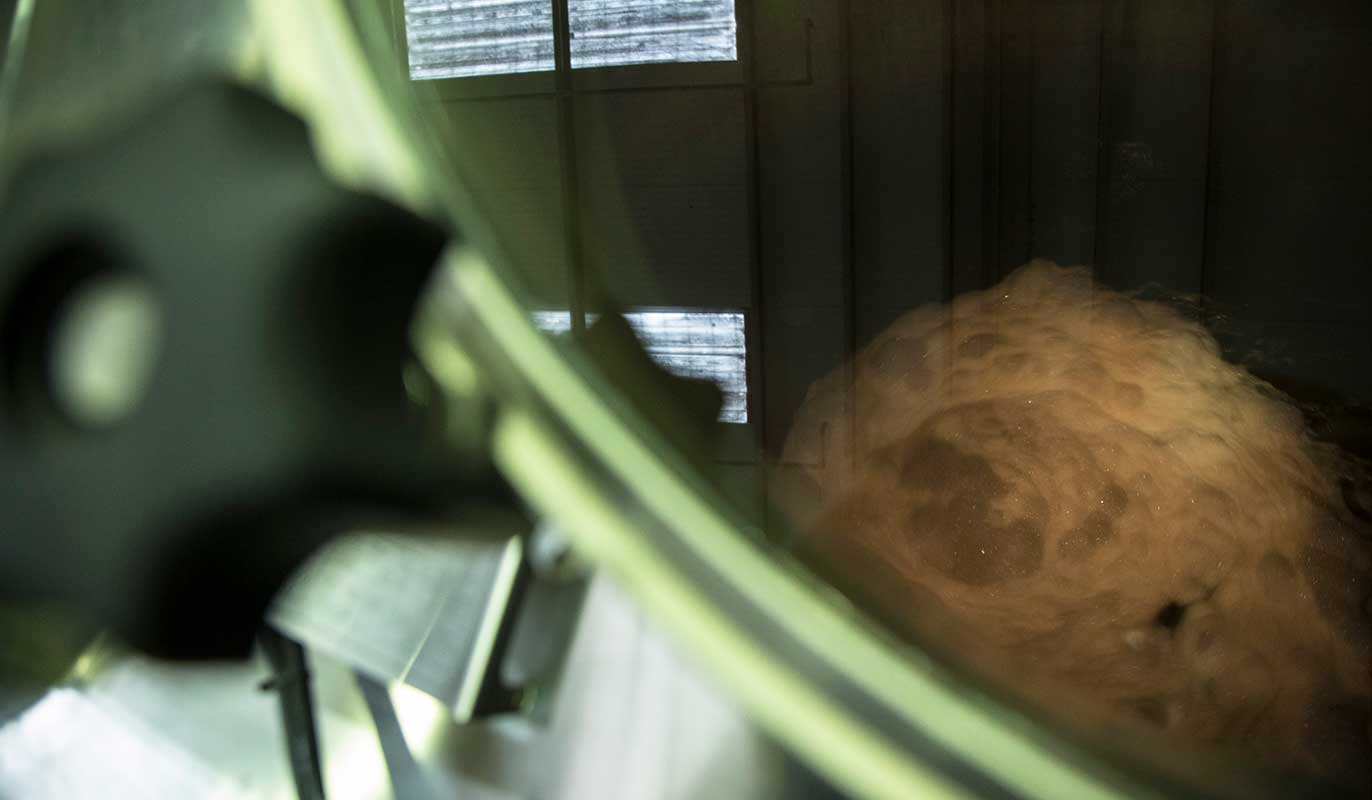

Fermentation

Located in a 150-year-old renovated dairy barn, WhistlePig’s distillery is the culmination of five diligent years. Opened in 2015, we distill 7 days a week in our unique copper pot still designed by world-renowned Master Distiller Dave Pickerell.

-

Distillation

Located in a 150-year-old renovated dairy barn, WhistlePig’s distillery is the culmination of five diligent years. Opened in 2015, we distill 7 days a week in our unique copper pot still designed by world-renowned Master Distiller Dave Pickerell.

Maturation

The wood management policy at Midleton distillery is regarded as pioneering and world class.

This policy commences with the barrel manufacturers, mainly in Spain, America and Portugal and also in Sicily and Cuba. Over many decades, the Midleton distillery maturation managers, sometimes referred to as the ‘wizards of wood’, have developed close alliances with the owners of specific cooperages and have set exacting standards of quality for the oak casks which are used for maturation at the Midleton Distillery. In the case of fortified wines, all casks are manufactured by the cooperage according to Midleton Distillery’s specifications, and are then effectively loaned to the Bodega or Quinta to be seasoned with sherry, port or other fortified wines. Then, when the oak casks are deemed to be properly seasoned, and only in certain weather conditions, the casks are requested to be ‘sent home’ to Midleton distillery. Additionally, Midleton Distillery has long established relationships with American whiskey distilleries from whom only the highest quality casks, most often ex-bourbon, are sourced.

So critical is the cask choice on the final flavour of the whiskey that maturation is sometimes referred to as the 'fourth ingredient' in whiskey making.

-

Bourbon Barrel

Bourbon Barrels are made from American white oak, Quercus alba, and have a typical capacity of 200 litres. Many of these barrels are manufactured in the state of Kentucky, and have held Bourbon whiskey for a period of 3 or 4 years prior to being shipped to Ireland. Only 1st quality seasoned casks are purchased for use at the Midleton distillery. On occasion, a small quantity of brand new or 'virgin' Bourbon barrels are purchased for the maturation of spirit.

-

Sherry Butt

These large casks, manufactured by hand at Jerez de la Frontera, Spain, are made from European oak, Quercus robur, and have a typical capacity of 500 litres. The butts used to mature whiskeys at Midleton are constructed specially for the Midleton Distillery using strict guidelines. Prior to being 'shipped home', the butts will have held sherry wine for two years.